Storage Pole Machine Shed Design Drafts 30x72 - Find Out How To Easily Plan And Assemble Your Own Do-It-Yourself Shed

The framing of a shed is an important step in storage shed assembly blueprints because it stiffens up the plywood boards and supports the roof. To build a wall frame you will need 2x4 pieces of wood and either nails or screws. Cut the timbers to the shed plan's specified measurements for your back wall frame. Once the wood is cut you can connect the pieces with screws to arrange a frame. The key to easily framing the exterior outhouse walls is to make sure the walls are square and level.

Support your wall by placing more 2X4s every two feet in the interior of the frame. In order to decrease weakness in your outhouse’s frame (https://shedconstructionplans.com/30x72-pole-machine-shed-plans) you can add flat sections of wood flush against the frame. When the rear wall is built flip it over to have it in the correct position to stand. Continue to square each frame as you build the last three walls. Once the back wall has been affixed you can raise all 4 exterior walls.

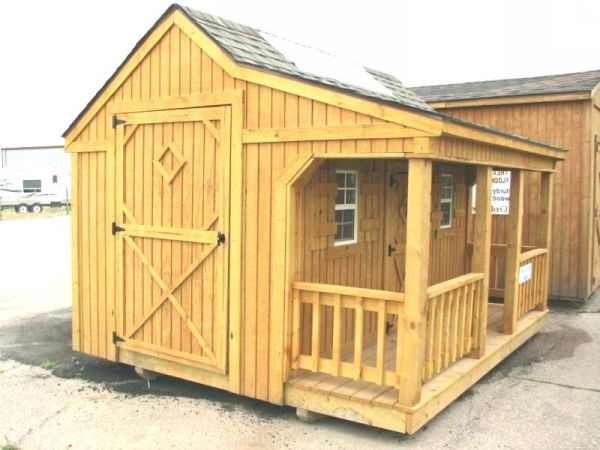

You outdoor shed construction diagrams can include the growing popularity of treated wooden outhouses. High-density polyethylene combined with wood creates an outbuilding that is resilient and sturdy. Prefabricated sheds are basically maintenance free because they never need painting and will not rust. Producers of manufactured wooden sheds have many size options and kits for shed extensions. Neither knowledge of carpentry nor many tools are necessary in constructing a simple prefabricated outbuilding.

Wooden sheds are extremely strong and can bear a lot of weight on their walls. Some models include an overhead loft area which allows more storage. A double-walled prefabricated shed will increase the sturdiness of your building. There are several different models of wooden sheds so you can pick the perfect one for you. Another bonus of manufactured sheds is that they are virtually effortless to renovate.

You need a suitable foundation for your outbuilding to rest upon or it will not last. Prepare your spot by first removing any grass and then covering the area of compacted soil with 2 inches of gravel. The gravel bed will make sure (this) that the soil beneath the outhouse will not wash away. There are two basic types of shed foundations known as on grade and permanent. sheds that are smaller than 200 feet square are best constructed upon on-grade foundations.

These smaller foundations are typically made of solid concrete blocks or wooden timbers placed directly on the ground. When placing timber directly on the ground be sure that it is green or pressure-treated. If you opt to use blocks be sure to choose ones made of solid cement as hollow-core wall blocks will crack under the weight of the building. To make a supportive on grade foundation just lay out your blocks or skids in straight evenly spaced rows. You will be able to enjoy a outhouse with a long life by giving it the foundation it needs to last.

Roof trusses help because not only do they support its roof but they also stabilize the walls. A great tip is to first build roof trusses on the floor and then raise each truss into position after the walls are up. During build-up be sure that there is no chance of rain so that none of your work gets wet during the process. Framing a roof in the traditional manner using individual rafters can be a challenge for someone who has never tried.

You can buy prefabricated roof trusses that will save you time and spare your knees. Roof trusses consist of a prefabricated assembly of two rafters fastened to a ceiling joist. Plywood reinforcement plates should be used to hold roof trusses together. When placing the trusses in your roof you should place them over wall studs. Any beginner can learn how to use industrial trusses for roofing. Any constructing center or lumber work area should carry different options for trusses.