Patio Lean To Shed Schematics 8x8 - Matters To Contemplate While Putting together A Simple Shed

Deterioration of your shed’s floor is inevitable if it isn’t constructed correctly. Always include pressure-treated lumber in the outhouse schematics (https://shedconstructionplans.com/8x8-lean-to-shed-plans) when building the floor frame of the outhouse. Untreated construction lumber may cost less but eventually it will rot and ruin your building. You will also need joists that go around the perimeter of the frame and mudsills. The mudsill is a 2x6 piece of lumber which rests on top of the foundation. Floor joists rest above the mudsill to support the outbuilding's walls while the band joist closes it off from the outdoors. Look for plywood that is exterior grade to put down as flooring in your outbuilding. Never use plywood thinner than ¾-inch because the floor will flex between joists. To increase the firmness of your floor invest in grooved plywood that fastens together. Fasten down the plywood with 2-inch long galvanized decking screws.

When making your outdoor outbuilding assembly diagrams consider using polyvinyl chloride as a convenient material for your outbuilding. Vinyl is the second most fabricated plastic by volume worldwide after polyethylene. Windows made of vinyl became popular during the energy crisis of the early 1970s in the US. PVC windows are easy to match to your outhouse as they offer a myriad of design and color options. Windows made of vinyl require very little maintenance and never need to be sanded or painted.

Compared with other window materials polyvinyl windows are great thermal insulators. Thermoplastics like vinyl can easily be melted and remolded into new products without losing any of its chemical features. Do not pick vinyl windows that are too large as they will not be particularly strong or rigid. Windows made of PVC material work well for a outbuilding but their simple appearance wouldn’t work for a home. Due to its quality and price PVC is still one of the most commonly used synthetics in outbuilding building.

In your outbuilding plans make sure your shed is safe and secure by adding some easy safeguards. Use good (click this link here) quality locking bars or padlocks on all windows and doors in your outbuilding. Install security lighting around your outbuildings and isolated locations. Secure and fortify the area around your outbuilding to protect all of your possessions. You can easily protect items in your outhouse by concealing the windows with drapes or blinds. outbuilding doors are notoriously easy to break open so strengthen them with heavy screws and bolts.

Mark valuable items with your house number and postcode using a UV pen or paint. You will better be able to get your property returned while also deterring thieves with prominent labeling. You can strengthen your outhouse’s resistance to vandals by fixing additional panels to the internal structure. Use a metal cage and keep it locked when your outhouse is unattended to ensure valuable equipment is safe.

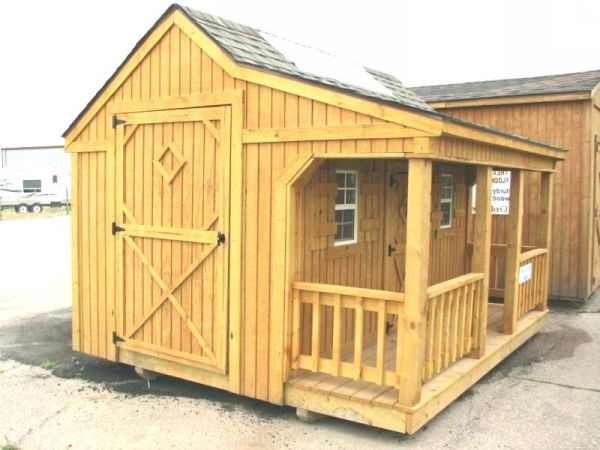

When making your storage shed blueprints consider including the new models made of treated wood. The plastic material used in addition with the wood makes the setting up strong yet lighter than other sheds. Prefabricated outhouses are basically maintenance free because they never need painting and will not rust. Producers of manufactured wooden outbuildings have many size options and kits for outbuilding extensions. Using a wooden outhouse kit is an easy task and it costs less than its plastic or metal counterpart.

Timber outhouses can handle much more weight than plastic or metal outhouses. Some models include an overhead loft area which allows more storage. Some manufacturers use combined support and a double-wall wooden panel construction for complete resilience. There are several different models of wooden outbuildings so you can pick the perfect one for you. Upgrading your prefabricated outhouse is easy with accessory options like skylights and shelving.